Introduction of CIL process

Dec 28, 2017#0183;#32;Oxygen is required for the reaction of the sodium cyanide with gold and silver. Theoretically, g oxygen is need to react one gram gold, however, in

WhatsApp)

WhatsApp)

Dec 28, 2017#0183;#32;Oxygen is required for the reaction of the sodium cyanide with gold and silver. Theoretically, g oxygen is need to react one gram gold, however, in

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Gold CIL production line Process Introduction. CIL (Carbon in Leach) process is the most efficient method to leaching and recovering gold from gold ore, The most protruding features is that leaching and adsorption are carried out at the same time, which greatly saves the cost of construction and operation.

The CIL process The carboninleach (CIL) process, illustrated in Figure 3 is a variation of the CIP process. In this process carbon is added directly to the leach circuit so that the leaching and adsorption processes proceed simultaneously. Capital cost is reduced, as

Factors influencing the rate of gold cyanide leaching and adsorption on activated carbon, and their impact on the design of CIL and CIP circuits June 2010 Conference: Precious Metals Conference

#0183;#32;Highlights Worldwide gold recovery on activated carbon grew from zero to almost 70% in twenty years from 1980. The stellar attributes of carbon gold plants led to complacency in the industry in designing and operating these plants. Most CIP and CIL plants are overdesigned and operated suboptimally. Optimum design criteria and operating conditions are easily determined with simple test

May 01, 2015#0183;#32;Plant design parameters for gold extraction, leach residence time and cyanide consumption are generally determined from standard benchscale bottle roll or agitation leach tests. The application of laboratory data to process design has essentially evolved from the testing of oxide or low cyanideconsuming ores. Such scaleup factors may not be appropriate for ores that deplete cyanide

Gold cyanidation process, like any other process, is affected by several parameters such as pH, temperature, slurry density, particle size, oxygen, cyanide concentration, agitation and the presence of other minerals in the ore (Marsden and House, 2006, Heath and Rumball, 1998, Ellis and Senanayake,

The cyanidation process is affected by a number of influential parameters, such as the availability of oxygen at the solidliquid interface, the pH and Eh of the solidsolvent suspension, the presence of ions other than CN in solution, the cyanide concentration, the particle size of the mineral, the temperature, the surface area of gold exposed, the purity of the gold, the

The influence of pyrite preoxidation in alkaline solutions on gold recovery by cyanidation from Twin Creek refractory gold ore in which pyrite was identified as the major sulfide mineral has been

CIL is developed based on allslime cyaniding followed by Zinc replacement, including thickening before leaching, leaching and adsorption, desorption of goldloaded carbon and electrodeposition, acidwashing and thermal regeneration, gold metallurgy. The most outstanding feature of CIL process is that leaching and absorption are simultaneous, in this way can save the agitation tank and the

The dissolution of gold through cyanidation, either Carbon in Pulp (CIP) or Carbon in Leach (CIL), is an oxidizing reaction. Generally added oxygen, in the form of dissolved oxygen in solution, improves the process as the rate of gold dissolution is directly proportional to the amount of

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

The CIL (Carbon in Leach) circuit is an intermediate stage in the production of gold. The process involves dissolving the solid gold particles into solution using a process know as cyanidation. The dissolved gold in solution is adsorbed onto activated carbon. When the carbon is loaded

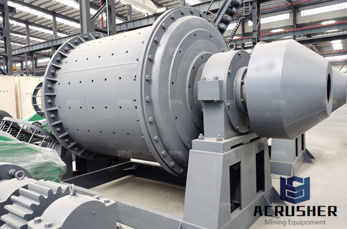

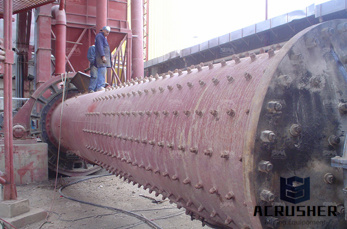

Gold CIL Production Line,Gold CIL Process,Gold CIL Plant

Since the cyanide leaching of gold requires oxygen, aeration and gas dispersion play an important role. Several studies have shown that the rate of dissolution of gold in cyanide solution is directly proportional to the amount of oxygen present in solution (Kondos et al. 1996; Ling et al. 1996; Lima and Hodouin 2005). The volumetric mass transfer

Influence of oxygen Whilst cyanide is one of the major drivers if not the major driver of gold dissolution, it cannot be viewed in isolation particularly in respect to the relationship between cyanide and oxygen derived from Elsners equation: [1] From the Equation, it is apparent that both cyanide and oxygen are required in an aqueous solution in order to leach gold. For the leaching of pure gold, the stoichiometry of

The global gold industry loses an estimated 25B of theoretically recoverable gold each year, with a significant portion of the losses caused by variable (and unmeasured) process performance. Gold mines collect a large amount of measurement data in an effort to improve control and reduce

PDF | On Jun 10, 2010, Alex Mezei published Factors influencing the rate of gold cyanide leaching and adsorption on activated carbon, and their impact on the design of CIL and CIP circuits | Find

Some gold bearing ores also contain active constituents which adsorb the leached gold and thus reduce gold recovery. The use of CIL can reduce or eliminate the loss of gold by the process of competitive adsorption. ALS Metallurgy can perform laboratory scale CIL tests and compare the results with conventional cyanidation.

May 01, 2011#0183;#32;Highlights Worldwide gold recovery on activated carbon grew from zero to almost 70% in twenty years from 1980. The stellar attributes of carbon gold plants led to complacency in the industry in designing and operating these plants. Most CIP and CIL plants are overdesigned and operated suboptimally. Optimum design criteria and operating conditions are easily determined with simple test

THE RECOVERY OF GOLD BY CY ANIDATION AND CIP/CIL PROCESSING 2 Cyanidation chemistry 2 Adsorption of aurocyanide onto activated carbon 3 Adsorption of aurocyanide at the ore surface 4 CIP/CIL processing of ores 5 Cyanide losses during CIP /CIL processing 7 Modelling of the CIP/CIL process 8

Decreasing level. of viscosity and increasing dissolve oxygen means higher dissolution rate will achieved and will give higher gold extraction levels and also impact on getting higher throughput. By that improvements, average gold extraction in 2013 is increase

WhatsApp)

WhatsApp)