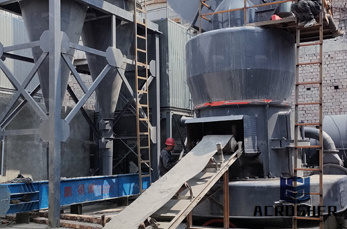

Media Charging Process For Cement Mill

media charging process for cement mill. Bells Mill PTA. Welcome to the Bells Mill PTA Website! Join the PTA or browse/search this site for PTA events and activities.

WhatsApp)

WhatsApp)

media charging process for cement mill. Bells Mill PTA. Welcome to the Bells Mill PTA Website! Join the PTA or browse/search this site for PTA events and activities.

Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding clinker requires a lot of energy. How easy a particular clinker is to grind (quot;grindabilityquot;) is not always easy to predict, but large clusters of belite due to coarse silica in the feed are difficult to grind.

effects of grinding media shapes on ball mill performance. Spherical grinding media are predominantly used in final stages of ore grinding Considering that worn balls in an industrial mill charge constitute about 15 to 40.. processing, cement production, power plants and pharmaceutical industries.

To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with 20 mm balls and 20 #215; 20 mm cylinders on six different size fractions, + mm, + mm, + mm, + mm, + mm and + mm of cement clinkers, were studied in a laboratory scale ball mill.

Media Charging In Cement Mill. Grinding media grinding balls for cement plantsrinding media for the variations in cement manufacturing changing impact conditions can cause conventional grinding media to either work harden or cause spalling thus shortening working life increasing downtime and increasing costsearn more cement mill dal teknik.

View from AA 1QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 na2elll CEMENT INDUSTRY Cement Mill

Cement Mill Grinding Media Page 1 Of 1 . Nov 01, 2017 re Cement Mill Grinding Media H there, These are just the basics if you want to accurately do it you have to fill it up to 80% BC and then do a longitudinal sieving and then correct the BC based on the results The biggest ball determination is explained and it is based on material hardness and biggest size Let me know if you need more info

#0183;#32;Report on Cement manufacturing process 1. A Report on Internship Taken At DCM Shriram Limited Kota (Raj.) Submitted in partial fulfillment of the requirement for the degree of Bachelor of Technology, Mechanical Engineering Duration June 5, 2015 July 20,2015 Academic session 201516 Submitted to Mr. Sanjeev Mittal (GMCement, DCM) amp; HOD Dept. of mechanical Engineering.

#0183;#32;The effect of the media shape on grinding kinetics of cement clinker in a ball mill was investigated. Results indicated that cement clinkers obey firstorder breakage kinetics in the case of both balls and cylinders. The specific rate of breakage provided by cylinders is higher than that of balls.

The objective of this study is to investigate the effect of ball size on the grinding kinetics of cement clinker in a ball grinding media used for the tests were 20 mm, 30 mm and 40 size + mm monosize specific rates of breakage,primary breakage distribution function and particle size distribution were compared for different diameter shows

Re: Request for feedback for a Two Chamber Cement Mill Ball Charge and Longitudinal Sieve Analysis. As per your given mill details.(mill output assumed to be 45 tons / hr) for more details you can contact me at vikprocem . It is not so easy to understand the cement

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL power plants, cement Grinding media wear Get Price Ball charges calculators The Cement Grinding Office

The ball mill is widely applied in mineral classification, cement, fireproof materials, glass, pottery, chemical industry and so on. The ball mill can grind all kinds of rocks and grinding materials.

#0183;#32;Optimization of Cement Grinding Operation in Ball Mills. Contact Us #187; . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

#0183;#32;Grinding Media Size Effect The ability to operate a mill with smallerdiameter grinding media greatly increases the mill''s efficiency and can overall further increase the quality of product through finer grinding. However, smaller grinding beads are more prone to hydraulic packing due to their decrease in mass per bead.

#0183;#32;CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT The first compartment shell lining must assure an efficient lifting effect of grinding media charge so that the grinding media give of the grinding media. Note: Others accept the limit of the degree of ball charge between 28% and 34% Mill Charging:

CEMENT MILL OPTIMISATION CASE STUDY Batra*, quality spare parts and consumables like grinding media . Ball mills are predominantly used machines for grinding in the cement Based on the empty height measurements, charging of grinding media in Chambers I amp; II calculated as equivalent to degree of filling of 22% amp; 21%

grinding media ratio in cement mill,pew series crusher is born with innovative significance. It is newly designed by our experts on basis of their more than 20 years. grinding media charge calculation in cement mill . grinding media percentage in cement mill; ppt on ball mill grinding media in cement industry; grinding media used in cement mill;

media charging in cement mills. grinding media charging in ball mill YouTube. 16 May 2014 grinding media charging in ball mill, Links: EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL A load beam was used to measure the torque exerted by the charge.

Energy Efficiency Improvement Opportunities for the Cement Industry. Improved grinding media (ball mills) Kiln GJ/t clinker, while data shows savings of GJ/t clinker (or GJ/t cement CemStar #174; charges a royalty fee

WhatsApp)

WhatsApp)